Piston skirt coating is becoming the norm in the performance racing world and has many benefits.

Problem:

Power can be lost through heat and friction caused by the motion of the pistons in the cylinders. Piston movement also causes scuffing.

Advantage:

Coat the piston skirts with a permanent solid film lubricant.

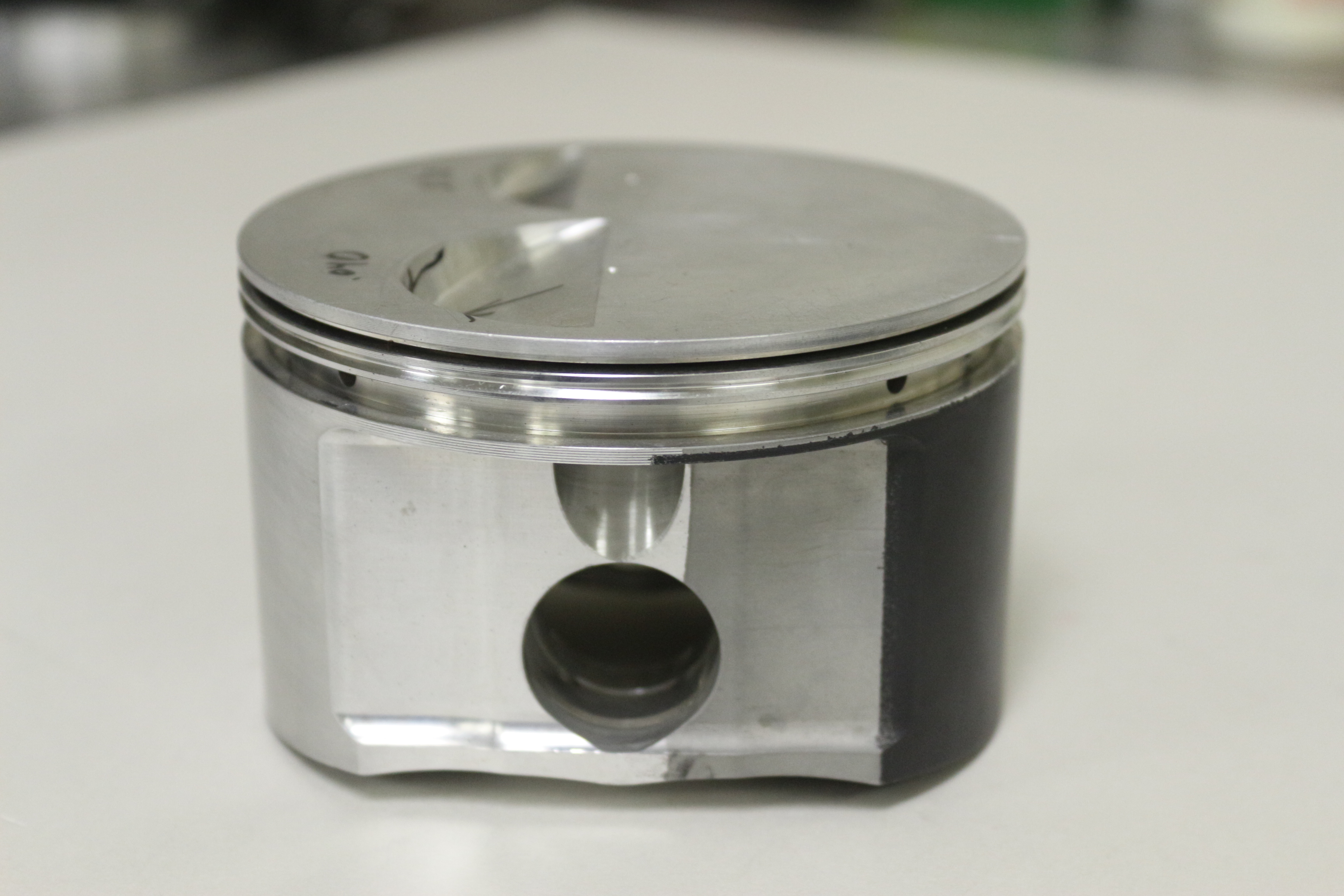

Pistons are in constant motion while the motor is running. It is very important that it moves up and down as efficiently as possible, especially in today’s performance engines. The piston skirt helps guide the piston as it moves in the cylinder and plays an important role in keeping wear and friction to a minimum.

Piston skirt coatings were developed at the end of the 1960s to reduce friction and scuffing. For high-performance engines with aluminum blocks a iron coating is used. There are a number of benefits of skirt coating:

Benefits of piston skirt coating:

- Frees up horse power normally lost to friction.

- Provides back-up lubrication if the primary lubrication has gone

- Reduces wear which increases engine life

- Meet the demands of high revving, short piston skirt and long rod motors

- Reduces heat that can cause galling and seizing

- Produces tighter piston-to-wall clearance

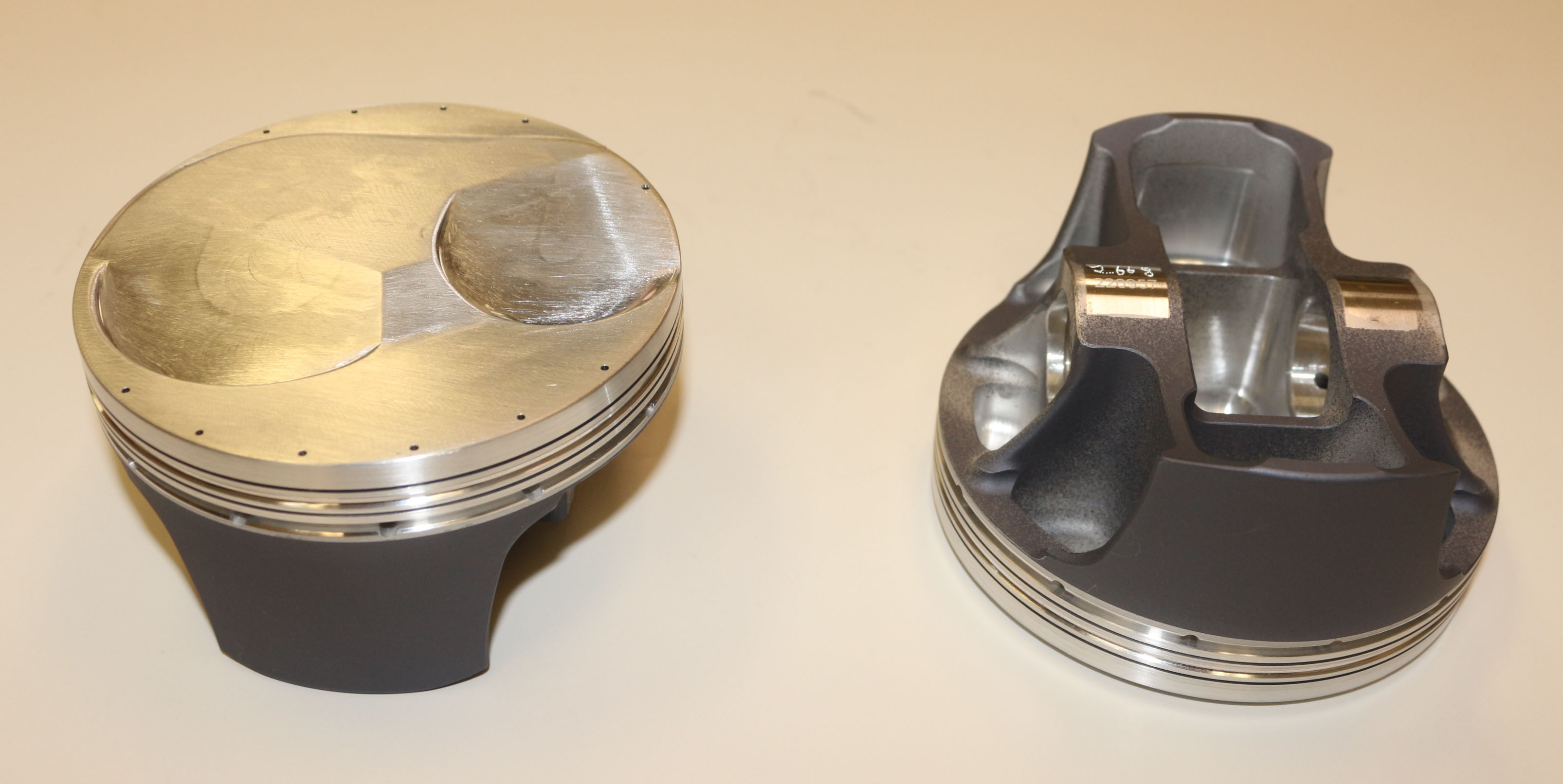

The coating provides a permanent solid film lubricant for this type of application. It can handle temperatures well over 2000° F, is water based, contains no solvents so it has no hazardous fumes. It is a high pressure lubricant and requires no clearance changes to compensate for the coating. Following are the steps in the coating process:

Process

Clean the pistons

Oil, dirt, debris and all other surface contaminants must be completely removed. If the surface is not properly cleaned, the coating can bead or bubble during baking.

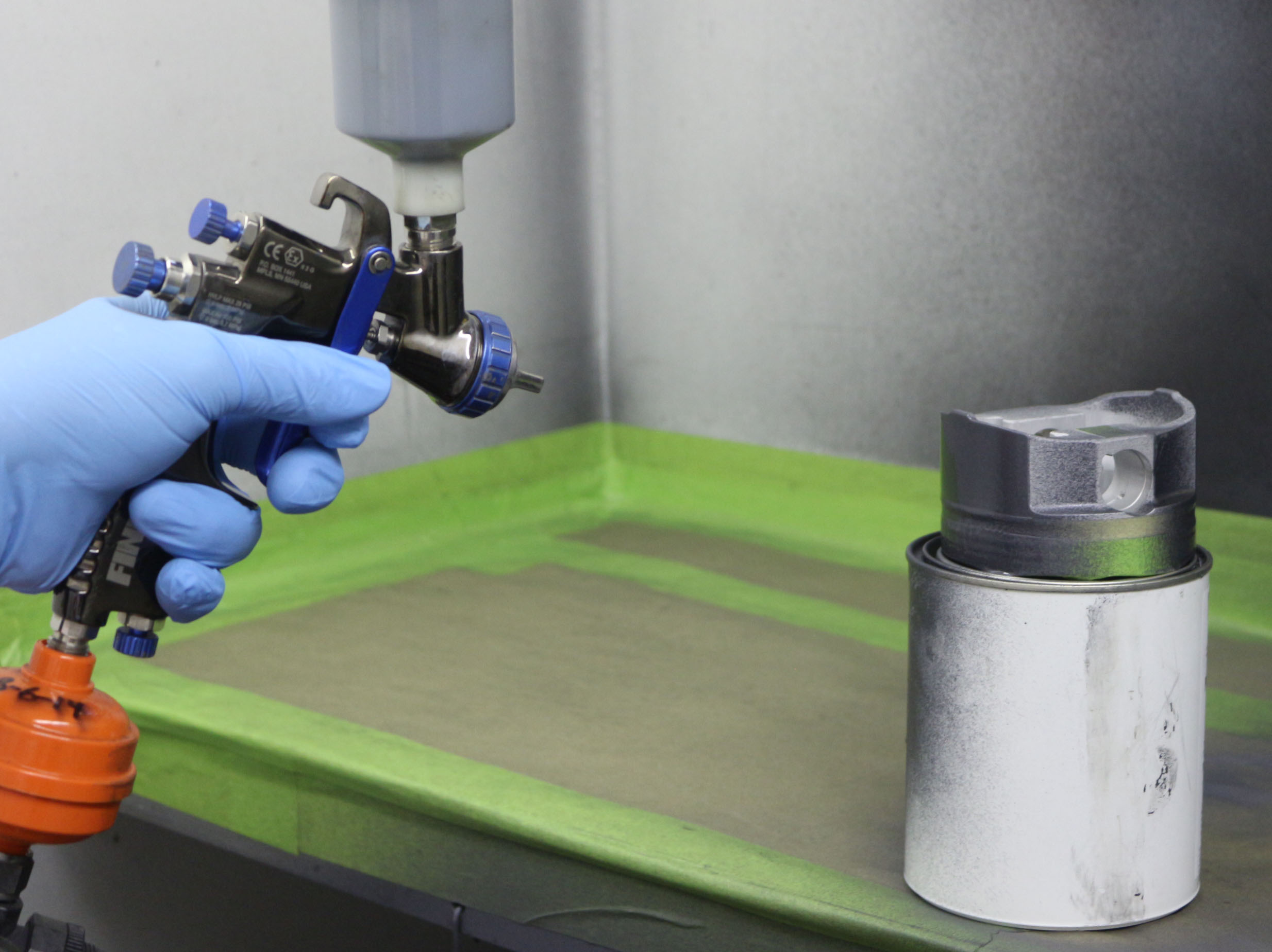

Spray coat

The spray pressure must be set just right. If the pressure is too high, the coating goes down flat and rough. If too low an ‘orange peel’ effect results and the coating may ball up during baking. The nozzle size must be adjusted so the spray comes out evenly without droplets and to avoid the film from being too thick on the part.

Bake

Bake for 1 hour.

At Patterson Racing we can take care of the entire process. Just give us a call and we will get it started. You can bring in your own pistons or better yet have us supply them so we can make sure to find the best ones for your high performance needs. We can request the manufacturer to make them to the right specifications including compression ratio, compression height and bore size for your block. We recommend using Total Seal rings for optimum clearance & better sealing.